Exactly weighed and safely loaded: our bulk loading

Deliver your product to your end customers without additional packaging

There are many ways of transporting goods. While some of your end customers use the classic bag for the efficient further processing of your products, others prefer the delivery of your goods in bulk without additional packaging, also for the sake of the environment. For this purpose, your products are loaded directly into silo trucks, containers or railway wagons.

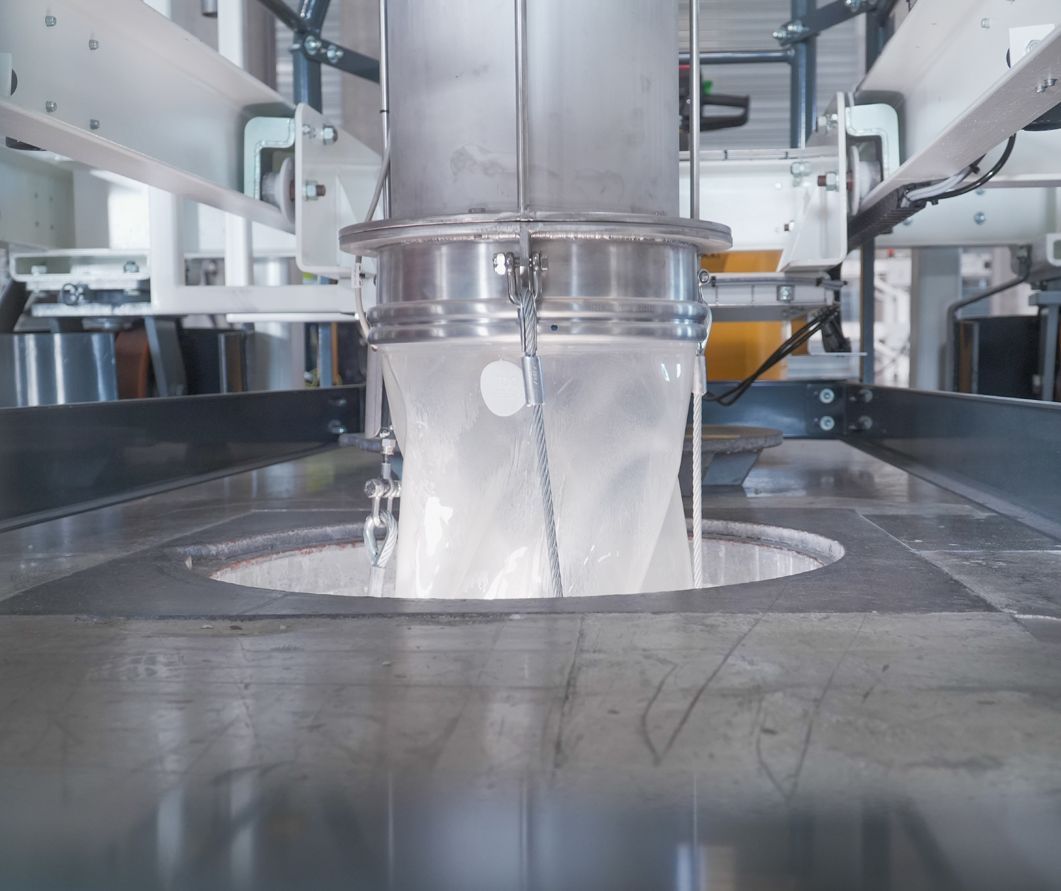

For bulk loading of your products, we combine our classic net weigher with our bulk loading head in a machine frame. They form a common unit that is placed directly under the outlet of your silo and docked to it in a dust-tight manner.

For the loading process, the silo truck or the railway wagon is parked and secured exactly below the loading hatch of your loading area - if desired, with the support of a video camera.The loading hatches of the vehicle as well as on the loading level of your building are opened. Our bulk loading head moves into the loading hatch of the silo truck or railway wagon.

Then our net weigher, located above the loading head, weighs your product in a fast and accurate weigh. It reliably discharges it via our loading head onto the loading area of the silo truck or railway wagon. The loading head channels the product thus ensuring that there is no loss of product or contamination of the loading environment during the loading process.

The filling level in the vehicle is monitored during the entire loading process. Overfilling of the vehicle is not possible.

Economical product dispatch

Your advantages at a glance

- Optimum utilisation of the available loading space, reduced transport costs

- Fast, safe and clean product loading with simultaneous precise product weighing and dosing

- Costs savings: no additional infrastructure and intermediate product transports required, reduced packaging material needs

- Intuitive operation via clearly structured operator terminal

- High reliability and availability due to robust and low-maintenance design

- Available as an option: precise stopping of the truck under the loading head thanks to video monitoring

Stay flexible: pack your product into bags or load it in bulk

How modern multi-level concepts and mobile machine designs work

Today, product silo farms are often realised as a multi-level concept. On the first floor, mobile form-fill-seal (FFS) packing machine or big bag filling stations are used for filling products into bags. At floor level, space remains for loading silo trucks or railway wagons.

With our bulk loading station, which is also arranged in a mobile way on the first floor, you dose the load of the silo truck or railway wagon in a high-performance way by means of multi-fillings until the desired filling level is reached. To do this, the bulk loading station is precisely positioned under the silo ready for loading and pneumatically docked to it.

This ensures the greatest possible flexiblity in your production while saving costs at the same time. Under consideration of product availability and production throughput, products from a large number of silos can either be filled into bags and big bags or loaded in bulk in parallel by a small number of machines.

Combine your bulk loading with our data management solutions

For even more data transparency

With our modern production and data management solutions, such as our shipping automation, you can organise your intralogistics in no time and optimise the traceability of your products. Especially in the area of bulk loading, the following data can be processed: